Vermeer Atlas Bore Planner

Page/Link:Page URL:HTML link:The Free Library. Retrieved Dec 22 2019 fromIn the early 1990s when compact horizontal directional drill (HDD)models began to appear on utility job sites, project owners oftenexpressed amazement when a drill operator brought the drill head to thesurface at or near the projected target.The technology was new and equipment operators were using makeshifttracking methods to monitor location of the drill head and estimate the'clock' position of its face in order to make directionaladjustments. Some in the industry concluded that effectively operating aHDD machine was an 'art' that not everyone could master.ILLUSTRATION OMITTEDThe industry changed quickly.The year 2000 was the height of the HDD boom, and equipment andtracking systems had evolved to the point that HDD installations wereroutinely successful. No longer a risky alternative, HDD was recognizedas the best construction option in a variety of conditions.However, while short, relatively straight shots in good soilconditions were easy to complete, it was obvious that long, difficultpilot bores with multiple elevation and left/ right direction should becarefully planned and that the drilling crew must be able to preciselyfollow the bore plan.The first bore planning tools utilized computer technology andsoftware that accepted project data and then produced a bore plan. Sincethat time, bore planning technology has advanced to include thecapabilities of monitoring bore progress in real time and documentingthe installation with as-built maps. Representatives of Ditch Witch and Vermeer recently discussed theircompany's current bore planning products and the benefits theyoffer to the HDD specialists and their clients.TMS PlusILLUSTRATION OMITTEDThe Ditch Witch bore planning product TMS Plus can be used with anybrand of HDD equipment, said John Bieberdorf, electronics divisionsenior product manager.

When used with Ditch Witch equipment, it offersthe additional capabilities of monitoring progress of a bore in realtime and providing an as-built map of the completed installation.Windows-based software works with Ditch Witch 750,742 and 8500tracking systems with interface cables to tracker displays and personalcomputers.' TMS is used to help determine the best bore path byidentifying critical points such as entry and exit points, topography changes and obstacles.' Said Bieberdorf. 'During the bore, TMSrecords the drill head position each time a new drill pipe is placed inthe ground.

It provides quick reference information on bend radius formore efficient use of drill pipe and installed product and compiles pipeinformation such as pipe number, depth, drill head roll angle, pitch,directional beacon temperature and battery level, date and time. As theproduct is pulled back. TMS records its actual position.'

To properly plan a bore. Bieberdorf said it is necessary to knowtopography elevation changes and known obstacles along the bore pathbetween the pilot bore's entry and exit points.After installing the TMS program on a PC. Planning the bore is afour step process:.

Open the TMS Plus program and access the planning grid and entertopography points relative to starting and exit points:. Enter obstacles along the bore path, such as roads, landscapefeatures and utility crossings:. Enter additional bore parameters such as cover depth, drill type,or pipe for calculating bend radius: and.

The TMS system generates a bore profile of the plan with thedriller having the ability to make any necessary adjustments,'Planning a bore in advance saves time, money and reducescomplications,'. said Bieberdorf. 'With a plan, the drilloperator knows when and where to guide the drill head to optimize theability lo avoid underground obstacles. With planning, the usable lifeof the drill pipe can be extended by following the recommended path thatwill not exceed the bend radius of the pipe.' Typically, Bieberdorf added, the planning process helps to uncoverprevious 'unknown' issues, thus helping to reducecomplications.' With TMS Plus.'

Concluded Bieberdorf. 'it ispossible to create multiple bore plans for the same job based ondifferent units or paths, giving the user options in how to complete thebore. After the completion of the bore, an as-built document can beprovided.' Bieberdorf cites a project in Washington's Cascade Mountainsas an example of the important role a TMS Plus system played on acomplex project.Apex Directional Drilling completed six bores to install duct forfiber optic cable with bore paths going up and down steep,heavily-wooded mountainsides and crossed canyons, some containingstreams and lakes (a report on the project was published in the May 2011issue of Underground Construction).

Geophysical information wascarefully gathered and inputted in the TMS Plus system.' Planning each bore was critical.' Said Apex PresidentMichael Lachner.

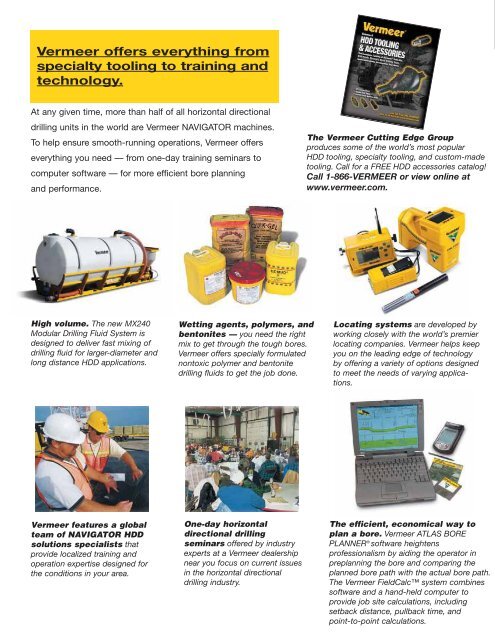

'With the severe downward angles, it was essentialto level off at exactly the correct point and then start up the oppositeslope at exactly the right spot lo hit the projected exit point.Profiles were critical, and we had to maintain a 40 to 45-foot depthbecause our plan was to use walk-over tracking equipment and if we wentdeeper, we could lose tracker signal.' Atlas Bore Planner/Terrain MapperVermeer offers two bore planning programs, said Duke Reynolds,trenchless solutions specialist.The Atlas Bore Planner software package can be downloaded from theVermeer website or from a CD. The current version operates with WindowsXP. Vista and Windows 7.

The Terrain Mapper is an add-on option thatcomes preloaded on a PalmPilot with laser, prism, rods and interfacecable.' Atlas Bore Planner software plans the bore before the jobbegins, said Reynolds. 'II takes into account the drill stem,tooling and product bend radiuses. It helps determine pay footage,proper set back of the machine, the optimal bore path, and estimates mudusage for the particular type of soil conditions where the bore will bemade.ILLUSTRATION OMITTED'The Terrain Mapper is a tool that the crew will use to mapthe topography of the area they are looking to complete their bore in.It can provide variances in terrain along a bore path and assist inmaking required calculations for the bore.

It uses a laser, prism andpoles to map the terrain and downloads that information into a handheldPalmPilot. From there, the information can be loaded into the Atlassystem.' 'The Terrain Mapper isn't always necessary,especially if boring will be fairly easy and the terrain is level. Weestimate Terrain Mapper is used about 25 percent of the time bores areplanned with the Atlas system.'

Atlas Bore Planner works on all Vermeer HDD equipment and is modelspecific.Reynolds said steps in planning a bore with the Atlas system are:. Bmw dis v57 user guide. Enter topography and elevation changes into the system;. Add existing utilities, creeks and rivers, roadways, etc.: and. Insert entry and target points, and the system plans the bore.If the Terrain Tracker is used, a crew member walks the bore pathwith the instrument, measuring elevation changes. Information is storedin the PalmPilot and downloaded into the Atlas Bore Planner.' Benefits of bore planning are efficiency andproductivity.' Said Reynolds.

'There are some jobs whereproject owners want a bore plan to be completed. On other projects,planning might not be required, but it can definitely help give acontractor the advantage during the bid process, and a contractor canuse the software to provide an overview of a job in order to plan howbest to do the project.' FOR MORE INFO:Ditch Witch(800) 654-6481, www.ditchwitch.comVermeer Corp.(888) 837-6337, www.vermeer.comBy Jeff Griffin Senior Editor.

Larger-diameter utility projects now often require contractors to submit detailed plans to help ensure adequate bend radius of the product being installed, account for other buried utilities and create an as-built bore profile after a job is complete. Faced with these new requirements, many contractors are left scrambling because creating a pre-bore plan manually can be an extremely time-consuming exercise.However, for the contractors who are committed to staying ahead of their customers’ needs and embracing new technology for the horizontal directional drilling (HDD) industry, adding bore planning tools can help streamline the process and provide a competitive advantage.Arizona-based R Directional Drilling & Underground Technology Inc. Performs utility installation work throughout the Southwest United States and has been using some form of bore planning software since opening its doors in 2006.

According to Ever Ruiz, estimator and project manager for R Directional Drilling, the company originally used Atlas Bore Planner computer software, and transitioned to the Vermeer BoreAid design tool when it was introduced to the market. The company has now converted most of their bore preplanning work to the Vermeer Projects software suite. Right Tool for the Job“Bore planning software and tools have come a long way in the last decade,” Ruiz says. “BoreAid has been a great tool for us when we are asked to help design a bore.

The program helps remind us to take into account soil conditions, product type, bend radius and the HDD rig that will be used on a job. After inputting the information, BoreAid design tool constructs a detailed proposed design that we can submit to our clients for approval.

The reports are much more professional than what we could do on our own.”. /. Advertisement./The BoreAid design tool has long been a staple in R Directional Drilling’s process, but now the company has found a way to create pre-bore plans on projects where they are required to show customers a bore profile before drilling has started. Different Tool for a Different Job“There are different requirements for creating a pre-bore plan and creating a design,” Ruiz says. “The bore path needs to be walked, existing utilities need to be identified with exact location and depths, and any other potential obstacles have to be accounted for. We used to collect all that information in the field and then come back to the office and add it into BoreAid design tool, but around a year ago we were introduced to another Vermeer productivity tool that has been designed specifically for this type of preplanning.”The tool R Directional Drilling & Underground Technology Inc. Is using today to perform pre-bore profiles is Vermeer Projects +BorePlan.

Ruiz says it’s more efficient than other methods they’ve tested to create a pre-bore plan.“Using an Apple iPad with Vermeer Projects loaded on it and a Trimble R1 GNSS receiver to provide accurate GPS coordinates, we can map the bore path and mark the location and depth of any other utilities or obstacles,” he says. “The Vermeer Projects tool gives us the ability to do almost everything in the field, but we can still make adjustments from a computer if needed.”The data collected in the field is then integrated with a Google Maps image of the jobsite and shared with utility customers.

The pre-bore plan includes the intended bore path whiteline, potholing locations and marked utilities. The plan presented also includes specific HDD information, including bend radius and rod-by-rod details.“By presenting this level of detail, our customers can see that we’ve thought through all the necessary aspects of a bore,” Ruiz adds. “Sometimes, we’ll be asked to change a plan because of information we didn’t know ahead of time, which is easy to do in Vermeer Projects. The tool R Directional Drilling & Underground Technology Inc.

Is using for pre-bore profiles, Vermeer Projects +BorePlan, allows the company to collect GPS coordinates so the company can map the bore path and mark the location and depth of any other utilities or obstacles. Preplanning RequirementsFor the team at R Directional Drilling & Underground Technology, developing a preplanned bore path was not required by any of their customers until a few years ago.“The local gas company we do a lot of work with started to ask for it as part of the project scope,” Ruiz says. “Now, they require it for all their steel pipeline work, ranging in size from 8 in. (20.3 cm) and up. There are also times when we are required to do preplanning on some plastic and PVC pipes, but usually there is some kind of special circumstance for those requests.”One of the special circumstances occurred earlier this year on a waterline job that R Directional Drilling worked on near Phoenix. The team was tasked with installing 12-in. (30.5 cm) fusible PVC and had to cross under some canals.

Vermeer Bore Planning Software

There was limited space in those areas, and the team had concerns about the allowable bend radius. So, they sent a few members of their team out with an iPad loaded with Vermeer Projects and a GPS antenna to measure the area and plot a bore path that would keep everything within an acceptable range.“While preplanning wasn’t necessarily customer mandated, we created a pre-bore profile anyway, because it would help our team be more efficient on the project and help us complete the job right the first time,” Ruiz says. “In some cases, customers tell us preplanning needs to be done, while for others, it’s just a good idea for our own peace of mind.” Raising the BarThe team at R Directional Drilling & Underground Technology has an investment and commitment to preplanning, helping them secure work for years to come. The team is just starting a new 6,000-ft (1,828.8 m) gas line project for a local utility company, and Ruiz says tools like Vermeer Projects and BoreAid design tool have provided them with a real competitive advantage.“These bore planning tools have helped us reduce the amount of time it would typically take to do the preplanning work, and we’re able to provide customers with professional reporting,” he says. “Those two things alone help set us apart from competitors bidding on the same job.

Of course, these tools are just a part of the process; we’ve always been an organization committed to doing things the right way, which means we’re always looking to improve.”R Directional Drilling’s commitment to constant improvement has helped set the course for a bright future. The company continues to grow in size, and the scale of the projects they perform continue to expand.Kayla Breja is senior product marketing specialist for utility and productivity tools at Vermeer Corp, based in Pella, Iowa. Vermeer, the Vermeer logo, Atlas BorePlanner and BoreAid are trademarks of Vermeer Manufacturing Co. In the United States and/or other countries. DCI, DigiTrack, Aurora and LWD are trademarks of Digital Control Inc. Trimble is a trademark of Trimble Inc. Google is a trademark of Alphabet, Inc.

Vermeer Bore Planner

IPad is a trademark of Apple Inc.